hardness test practical|types of hardness tests : manufacturer Try this practical with your students to measure the hardness of water samples and investigate the effect of boiling. Includes kit list and safety instructions. Resultado da 38'. 21'. 17'. O JOGO. Em um jogo muito movimentado e equilibrado, o PSG venceu o Monaco por 5 a 2, nesta sexta-feira, no jogo que abriu a 13ª .

{plog:ftitle_list}

web3 dias atrás · 5. Stake.us — 3.9/5 ⭐️. Stake.us is a cryptocurrency casino that provides new users with a 250,000 GC + $25 SC no-deposit bonus, just for signing up. The platform offers over 500 games from .

Try this practical with your students to measure the hardness of water samples and investigate the effect of boiling. Includes kit list and safety instructions.

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.from a hardness test can be used to provide critical material performance information and insight to the durability, strength, flexibility, and capabilities of a variety of component types from raw .Knowledge and insight into materialographic hardness testing – including how to test metallic and other materials, and the definitions, applications and conclusions of different hardness tests – .Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.

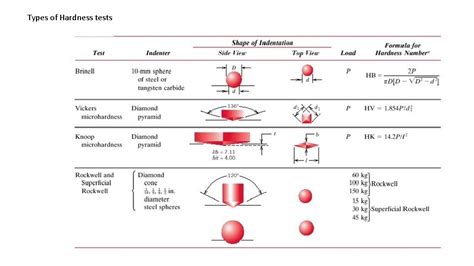

Classification, process, differentiation and practical recommendations. Here you will find useful information on the basics of hardness testing, the most common standardized test methods Rockwell, Brinell, Vickers and Knoop as well as . (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . In practice, these hardness tests could, for instance, assist in determining the viability of steel to be used in a high-pressure environment, such as a boiler. .

scratch test on skin

The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring theExperiment: Mechanical Testing- Impact & Hardness Testing Objective The main objective of this experiment is to introduce two important basic mechanical property tests; hardness . as nearly as practical, the service conditions. Factors to be considered include the nature of the applied load(s), its’ duration and the applicable environmental .

For practical reasons conversion tables are used to convert between one scale and another. Measuring Hardness. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a .

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. . 4 To gain the practical knowledge about Non-destructive testingBrinell Hardness Test: Rockwell Hardness Test: In Brinell Hardness Test the indenter is a spherical Tungsten Carbide Ball: For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup. There is no such limitation in Rockwell .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as . Specimen Shape and Gripping; Measurement of Load and Displacement; Displacement Measuring Devices; The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when examining outcomes.

types of hardness tests

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.This article reviews the factors that have a significant effect on the selection and interpretation of results of different hardness tests, namely, Brinell, Rockwell, Vickers, and Knoop tests.🕑 Reading time: 1 minute Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the [.]

The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. Grab this complete guide. Register; . Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. Register for the world’s largest manufacturing technology .PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test . Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the hardness of metals, alloys, and plastics, when compared to .

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection . Brinell Hardness Test: Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as . The choice is not only between the regular hardness test and superficial hardness test, with three different major loads for each, but also between the diamond indenter and the 1/16, 1/8, 1/4 and 1/2 in. diameter steel ball indenters.

scratch test on plants

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place. The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, mineralogy, and material science. The scale is qualitative, ranking minerals from 1 to 10, with 1 representing the softest mineral and 10 the hardest. The .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .Date Title Place Language Registration 12/18/2024, 08.30 am - 04.30 pm ical Basic training course for hardness testing in theory and practice

Application of Brinell Hardness Test. Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and therefore relatively large indent, it is frequently used to determine the hardness of the material which has . Certaincommercial. entities, equipment, ormaterials. may. be. identifiedin. this. document. in. order. todescribe. anexperimentalprocedure. or. concept. adequately .

types of hardness testing methods

types of hardness testers

hardness tester for thin material

webFazer um cosplay impecável é um grande desafio, mas a cosplayer brasileira @thaysekloppel mostrou que é possível alcançar a perfeição ao compartilhar em seu .

hardness test practical|types of hardness tests